Get a quote now

Fill out the form with your project details.

We operate throughout Italy: our team will review your request and get back to you within 24 hours.

Digital Twin

We transform the physical world into high-precision Digital Twins: from 3D surveying to Scan-to-CAD and BIM modeling for efficient asset management.

READY TO DESIGN

MEASUREMENTS THAT MATTER

FROM REAL TO DIGITAL

This website has

a low carbon

footprint.

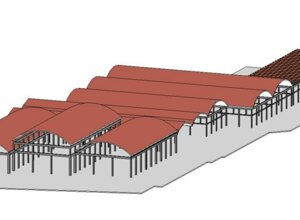

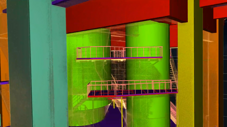

Scan-to-CAD & BIM models for revamping, maintenance, and layout optimization of production plants.

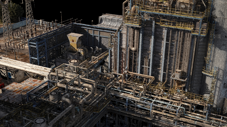

High-density digital models for dimensional checks, compliance, analysis, and intervention planning.

We turn complex structures into navigable Digital Twins using aerial photogrammetry and LiDAR surveys.

This page emits 0.16g of CO₂ per visit.

Learn more on Website Carbon.

Unprecedented efficiency

Offices:

Via Monte Napoleone 8, 20121 Milan (MI)

Via Pasquale De Virgilii 2, 66100 Chieti (CH)

FOR FURTHER INFORMATION

Tel.: +39 388 10 79 439

E-mail: info.it@netf.eu

VAT No.: 10397120964

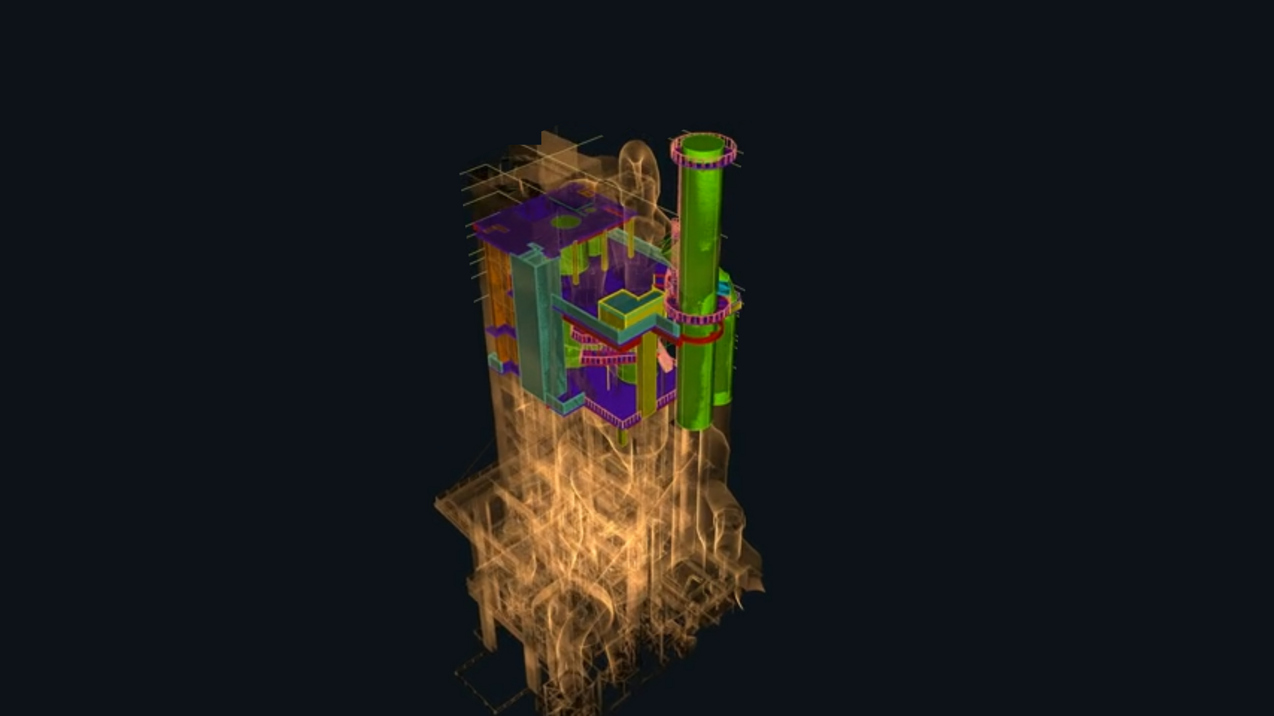

We create ultra-precise Digital Twins starting from 3D surveys carried out using aerial photogrammetry and LiDAR (Light Detection and Ranging), converting complex physical structures into detailed, reliable, and fully navigable digital models. Our process is designed to ensure geometric fidelity, metric accuracy, and maximum compatibility with the main design environments.

Through our Scan to CAD and Scan to BIM services, we generate high-density point clouds from which we develop three-dimensional technical models, ready to be used across all design stages. The Digital Twins we produce are strategic tools to support structural analyses, dimensional checks, compliance verification, and the design of new plants or expansions.

This technology is also essential for revamping activities, where a detailed understanding of the existing conditions enables precise interventions, optimizing time and resources while reducing margins of error. In addition, our digital models are an effective asset for document management, predictive maintenance, and continuous asset monitoring, contributing to improved technical governance of infrastructure.

Our approach is fully flexible and scalable to the specific context: we operate with the same effectiveness in open and confined spaces, even hard-to-access areas, ensuring operational safety, rapid data acquisition, and minimal interference with ongoing activities—thereby supporting business continuity.

Our Digital Twins are applied across a wide range of sectors, including industrial plants, manufacturing buildings, power stations, bridges and viaducts, utility networks, and civil works, providing clients with a practical tool to efficiently manage every phase of the asset lifecycle.

Why choose our Digital Twins

We create ultra-high-precision Digital Twins, transforming complex 3D surveys into reliable, navigable, metrically accurate digital models designed to support design, verification, and asset management. This approach delivers concrete, measurable benefits:

- Geometric fidelity and metric accuracy, ensured by aerial photogrammetry and LiDAR technology.

- High-density point clouds converted into technical models through Scan to CAD and Scan to BIM.

- Maximum compatibility with CAD/BIM environments and existing design workflows.

- Support for structural analyses, dimensional checks, and compliance verification.

- A strategic tool for revamping and expansions, based on an accurate understanding of the as-is condition.

- Reduced time, costs, and margins of error in decision-making and operational phases.

- Applicable in open and confined spaces, even hard-to-access areas, with full operational safety.

- Support for document management, predictive maintenance, and continuous asset monitoring.

The result is an operational Digital Twin—not just a representation—that supports the infrastructure throughout its entire lifecycle, improving control, planning, and technical governance.

Photo Gallery

.jpeg)

.jpeg)