Get a quote now

Fill out the form with your project details.

We operate throughout Italy: our team will review your request and get back to you within 24 hours.

Surveys and inspections in confined Spaces

Drone inspections in confined spaces: enhanced safety, high precision and detailed 3D models for effective asset management.

FAST DECISIONS

CLEAR

VISION

OPERATIONAL

SAFETY

.png)

This website has

a low carbon

footprint.

HD imagery and dedicated lighting to accurately detect wear, deposits, corrosion, and damage in hazardous environments.

We reduce exposure to operational risks and support execution in compliance with HSE procedures and requirements.

Quality assessments to define the asset’s current condition, set intervention priorities, and support operational decision-making.

This page emits 0.16g of CO₂ per visit.

Learn more on Website Carbon.

Unmatched

reliability

Offices:

Via Monte Napoleone 8, 20121 Milan (MI)

Via Pasquale De Virgilii 2, 66100 Chieti (CH)

FOR FURTHER INFORMATION

Tel.: +39 388 10 79 439

E-mail: info.it@netf.eu

VAT No.: 10397120964

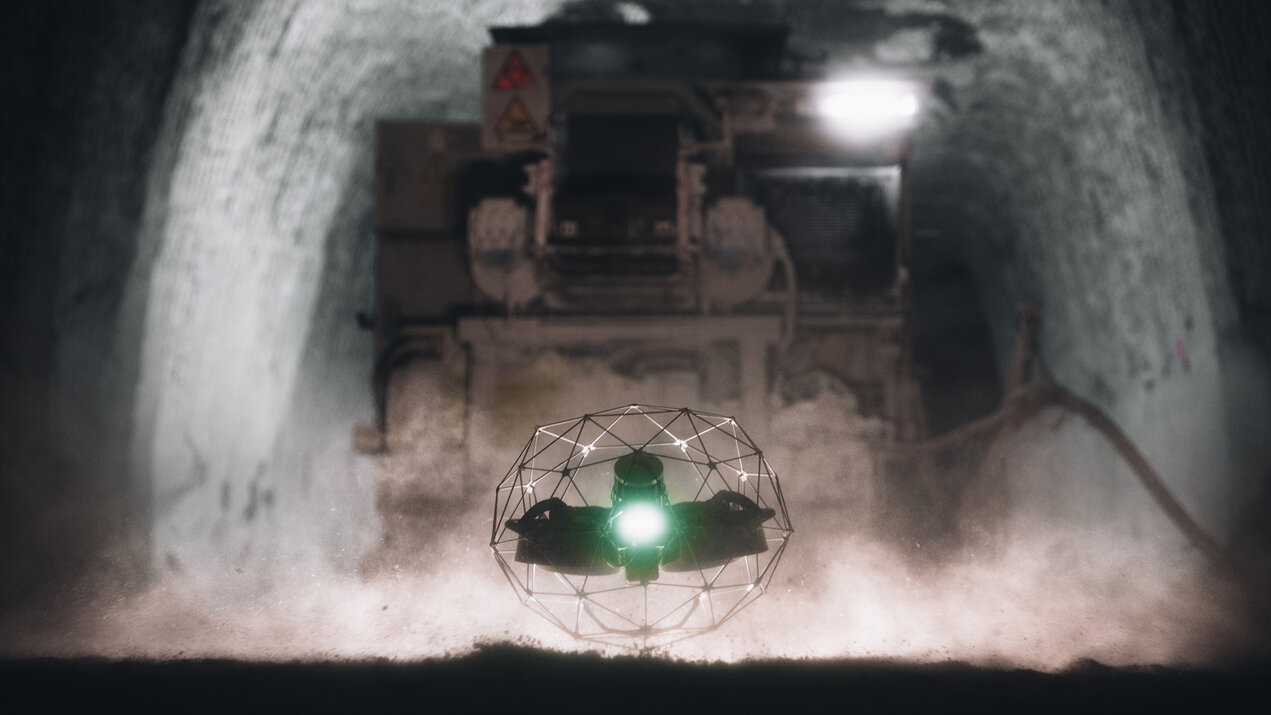

From accurate data acquisition through to the decision-making phase, our know-how and the use of specialized drones enhance our operational capability, enabling us to carry out advanced inspections in extremely complex and inaccessible environments, such as confined spaces and hostile settings. This approach drastically reduces personnel exposure to hazardous situations, increasing safety and efficiency.

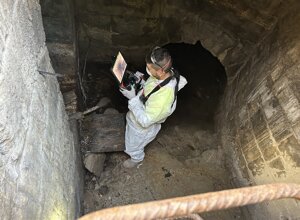

We successfully operate in the energy, chemical, Oil & Gas, and industrial sectors, as well as in the maintenance of critical infrastructure, working also in complex and confined environments such as unventilated crawl spaces, covered underground sections, utility tunnels and buried pipelines, manholes and technical chambers with limited ventilation and restricted access, where specific procedures, equipment, and expertise are required.

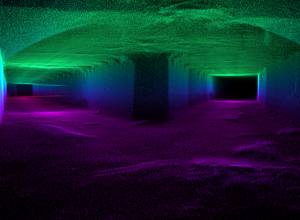

We use state-of-the-art RGB (Red, Green, Blue) sensors and radiometric thermal sensors to accurately detect any type of anomaly.The integration of LiDAR (Light Detection and Ranging) technology enables us to generate high-density point clouds, providing a detailed and reliable three-dimensional representation, ideal for the highest-level technical analysis.

All detected and analyzed anomalies are available both on our cloud platform and in PDF report format, with the ability to accurately measure dimensions, surface areas, volumes, and other parameters useful for technical analysis and intervention planning. It is also possible to promptly identify cracks, corrosion, water infiltration, and other signs of deterioration, which are essential for carrying out targeted and effective interventions.

Detailed Surveys

In confined and hostile environments, where access is limited or risky, LiDAR surveys represent the most advanced and safest solution for obtaining high-precision 3D data. Through indoor flight operations, we perform complete laser scans in total safety, even in conditions of complete darkness, the presence of dust, humidity, or complex structures.

This methodology is applied in numerous contexts, such as power generation plants, industrial facilities, underground infrastructure, and chemical plants, where it is essential to document with precision the internal geometry of spaces that are not directly accessible to humans.

The scan produces a high-density, georeferenced point cloud, which provides a detailed representation of the geometry of the surveyed environment.

This output provides the foundation for 2D/3D CAD modeling, integration into GIS platforms, and the creation of BIM models, enabling spatial analysis, technical design, asset digitalization, and intelligent infrastructure management.

Thanks to the georeferencing of the point cloud, the acquired data can be integrated with external surveys, existing plans, or future projects, ensuring metric consistency and maximum interoperability with leading technical software.

LiDAR surveys also make it possible to detect deformations, clashes/interferences, detachments, obstructions, and other critical conditions, providing objective, measurable information for every subsequent operational phase.

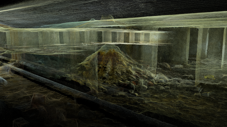

Culverted section

survey

.png)

In this video, we showcase the operational phases of a survey inside a culverted section, carried out using LiDAR technology and specialized drones for confined environments.

From on-site scanning to 3D modeling, we ensure accurate data and an efficient workflow, without exposing personnel to risk.

The integration of LiDAR surveying and digital analysis provides a detailed representation of the asset, enabling hydraulic studies and the planning of maintenance activities.

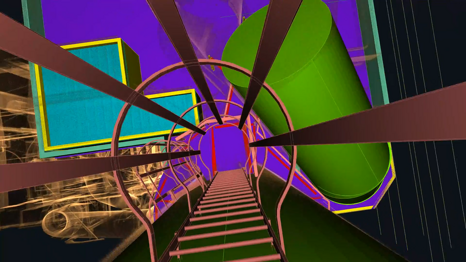

Internal Inspection of a Wind Turbine Blade

.png)

In this video, we showcase an internal inspection of a wind turbine blade.

The use of visual sensors enabled the detection of structural damage not visible from the outside, such as cracks, while ensuring total safety and no direct personnel access.

The operation was completed quickly, with full image and data acquisition, immediately available on our cloud platform for analysis and maintenance planning.

Benefits for your project

We carry out surveys and inspections in confined spaces using specialized drones, dedicated lighting, and latest-generation sensors, transforming difficult and hazardous environments into objective data and measurable 3D models. This approach delivers tangible benefits for safety, maintenance, and operational continuity:

- Drastic reduction of risk exposure: no manual access to hazardous areas, in full compliance with HSE procedures and requirements.

- Clear HD visibility even in critical conditions: darkness, dust, humidity, and complex geometries.

- Accurate anomaly detection: wear, deposits, corrosion, cracks, water infiltration, and signs of deterioration.

- RGB and radiometric thermal sensors to identify defects and abnormal variations in a non-invasive way.

- LiDAR for high-density point clouds: a detailed and reliable 3D representation of the indoor environment.

- Precise measurements of dimensions, surface areas, and volumes to support intervention planning and operational priorities.

- Interoperable outputs: a base for 2D/3D CAD modeling, GIS integration, and BIM models.

- Data available via cloud platform and PDF reports for traceability, sharing, and technical documentation.

The result is a safer, faster, and measurable method that supports timely operational decisions and targeted interventions—even on critical assets.

Photo Gallery

%20e%20n.7%20(superiore).png)