Get a quote now

Fill out the form with your project details.

We operate throughout Italy: our team will review your request and get back to you within 24 hours.

Drone inspections for industrial plants and infrastructure

From visual and thermal inspections to 3D modeling: we identify defects and anomalies to ensure safer and more efficient asset management.

MEASURABLE RESULTS

OPERATIONAL CONTINUITY

TECHNICAL REPORTS

This website has

a low carbon

footprint.

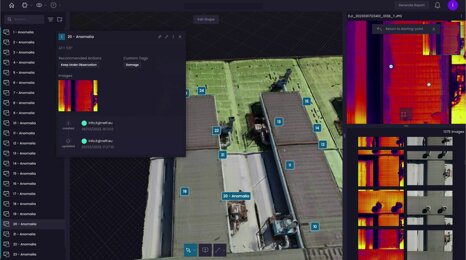

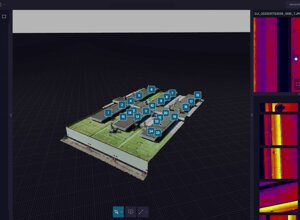

Cloud and PDF delivery, with measurements and precise localization of anomalies on the 3D model.

Safe inspections without direct personnel access to hazardous areas, ensuring plant operational continuity.

We identify anomalies and points of interest, turning inspections into data that supports maintenance.

This page emits 0.16g of CO₂ per visit.

Learn more on Website Carbon.

High standards

Offices:

Via Monte Napoleone 8, 20121 Milan (MI)

Via Pasquale De Virgilii 2, 66100 Chieti (CH)

FOR FURTHER INFORMATION

Tel.: +39 388 10 79 439

E-mail: info.it@netf.eu

VAT No.: 10397120964

Our drone-based visual inspections provide a highly detailed, ultra-precise aerial perspective, enabling the detection of anomalies directly on the asset’s 3D digital model. Each visual survey is translated into actionable data, allowing us to identify defects, discontinuities, or structural deterioration with unprecedented clarity.

All collected information is available both on our cloud platform and as PDF reports, with the ability to accurately measure dimensions, areas, volumes, and other parameters useful for technical analysis and intervention planning.

Our approach eliminates the risks associated with traditional inspections, removing the need for scaffolding, ropes, or manual access. The result is a leaner, safer, and faster methodology that significantly reduces time and operational costs, without interfering with ongoing activities.

.png)

Our advanced inspection service is applied across a wide range of industrial and infrastructural contexts: from the hydroelectric and chemical sectors to energy and thermal plants, industrial facilities, as well as penstocks, tanks, tunnels, reservoirs, and other complex structures, where operating safely and without interruptions is essential.

Beyond the visible

Drone-based thermographic inspections make it possible to detect anomalies and critical issues that cannot be identified through standard visual inspections. They represent a decisive evolution in monitoring the health condition of industrial and infrastructural assets, significantly raising the level of non-invasive analysis compared to traditional methods.

Thanks to the use of high-precision radiometric thermal cameras, we can detect temperature variations, energy losses, overheating, and other anomalies in large-scale, complex, hard-to-access, or potentially hazardous environments.

This approach not only enhances operator safety by avoiding direct access to high-risk areas, but also allows inspections to be carried out without interrupting plant operations, drastically reducing downtime and optimizing maintenance management.

The advantages of our advanced inspections

Our drone-based visual and thermographic inspections turn asset monitoring into a safer, faster, and measurable process, providing clear evidence directly on 3D models and technical reports. This approach delivers concrete advantages for analysis, maintenance, and intervention planning:

- 3D models and technical reports.

- Ultra-precise 3D models to identify anomalies and deterioration

- Accurate measurements (dimensions, areas, volumes)

- Cloud access and PDF reports for sharing and traceability

- No scaffolding or rope access: reduced operator risk

- Minimal disruption and shorter timelines

- Radiometric thermography to detect energy losses, overheating, and thermal anomalies

- Safe inspections in hazardous areas (tunnels, tanks, pipelines, industrial plants)

The result is a more complete and objective inspection process that enhances safety, accelerates decision-making, and makes maintenance more effective.

Photo Gallery

.png)